Cambio de Aceite de Motor

Preface

This is a basic walk-through for changing the oil on the VTX 1800. I have to say thanks to David from the VTXOA for snapping these pics and doing the initial write-up which served as a template for this write-up.

This is a simple job which only requires a few basic tools. As always undertake this project at your own risk, but with a little common sense this isn't very hard to do. I hope this helps.

Preparation/supplies

2 new crush washers available from HDL

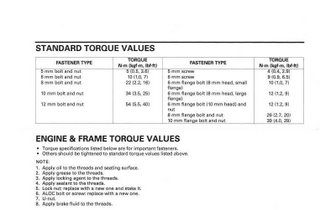

2 new crush washers available from HDL Torque wrench capable of 20ft/lbs to 22 ft/lbs

Torque wrench capable of 20ft/lbs to 22 ft/lbs 17mm socket

17mm socket Strap wrench or oil filter socket

Strap wrench or oil filter socket Funnel

Funnel Drain pan (whatever your choice is for draining oil into)

Drain pan (whatever your choice is for draining oil into) New filter - I run the OEM ones

New filter - I run the OEM ones 3.9 qts of your favorite oil

3.9 qts of your favorite oilProcess

I always start my oil changes with a quick trip around the block. I ride for about 2-3 minutes just to get the engine oil warmed up and moving. By doing this I get all the "junk" that settles in the motor mixed into the oil so that when I drain it comes out too. Plus warm oil flows better than cold oil so it should drain faster. I try to get my tools together before I make this trip so that as soon as I get back I can drain almost immediately. I know a couple of minutes won't make a huge difference, but I'm pretty anal about getting the old oil and as much "junk" out of the motor as possible.

So once I take my little trip I get my bike up on my "oil change blocks".

You can check these out over on my tools page.

Anyways, I use my motorcycle lift to raise the bike onto these blocks for oil changes, it's not as hard as it sounds and it makes changing the oil SO MUCH EASIER (no more busted knuckles)! Some people have made their own versions of these with the front end of the blocks cut on an angle so they can drive the bike right onto the blocks, and some people feel more comfortable changing the oil with the bike on the ground. I prefer my method but to each their own!

So with the bike ready to drain slide the drain pan under the bike, unscrew the dipstick (to allow air in as oil drains):

and remove the rear drain bolt with the 17mm socket:

Now we wait... While the oil is draining check out the crush washer on the drain bolt. If there is no washer there it may have fallen into the oil, unless you plan to replace it then fish it out of the drain pan. Give it a close inspection, make sure there are no big nicks or flaws in it. The service manual recommends replacing these with each oil change but if they still look ok then there's no reason you can't re-use it. If there is any doubt about the condition of the washer replace it, your safety isn't worth the $.50 or so to replace it.

I try to keep some of these on hand just in case I find myself needing to replace one at night or on a Sunday when I can't get one. I will say that in a pinch I have been able to find a replacement at the 24 hour AutoZone near my house, I just brought in the original for comparison - but they charged me an arm and a leg for it!

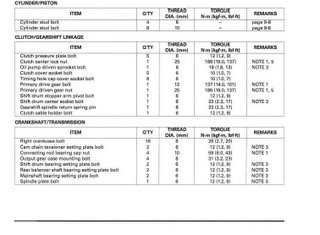

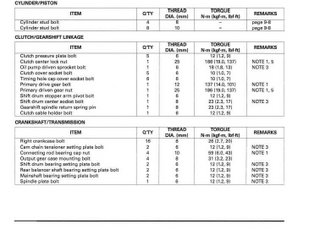

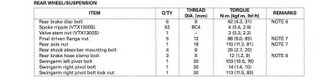

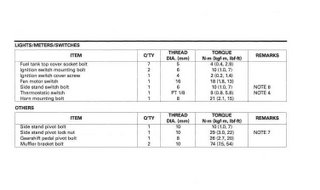

When the oil stops flowing from the rear drain replace the bolt and washer and tighten them to 22 ft/lbs.

Now move onto the front drain bolt:

Do the exact same thing for this one - remove, drain, inspect the washer, replace to 22 ft/lbs.

Now move back to the oil filter:

Use your filter socket, strap wrench, hand, whatever to remove the old filter. Sometimes they get a little stuck (this is especially true for bikes on the first oil change) so if worse comes to worse just punch a screwdriver through the filter (you're throwing it away anyway) and use that to unscrew it. With the filter removed let the remaining oil drain and check to make sure the gasket came off with the filter. Sometimes the rubber gasket on the old filter will stick to the engine case, installing the new filter over it can potentially leak - or worse drain all the oil suddenly in a worst case scenario. It's not a bad idea to check the old filter and visually inspect the engine case before installing the new filter.

Take a drop of new oil and coat the gasket on the new filter then thread it back onto the engine. Make sure you don't cross-thread the filter, it should spin right on with almost no resistance. The specific torque for the filter is 20 ft/lbs but I just seat the filter on the engine and snug it another 1/2 turn or so and I've never had a problem.

With the filter replaced and the 2 drain bolts/washers checked and torqued down we are now ready to add our 3.9 quarts of oil. Oil is a very personal choice so you can decide on what you want to run, I run Amsoil 10W-40 in my bike. If you want to try Amsoil you can order it from David Vain who is an outstanding dealer to work with. You can contact him at synthetics@vainenterprises.com or call him at 985-788-0554. If you're uncertain about your oil decision then maybe you should read Tapper's big oil article, it has given me a wealth of information regarding oil from someone who's done his homework.

Anyways, using the funnel dump all 4 quarts in quickly, pouring but not allowing the bottle to sit upside down and drain every little bit. After pouring all 4 quarts this way there is about .1 quart left between all 4 bottles so you added the required 3.9 quarts. There is some debate/discrepancy between folks about the proper method to refill the bike, this has led to some folks putting 5 and 6 quarts of oil into a bike that only requires the 3.9. What I've learned from working on these bikes is that the sticks in these bikes can vary slightly from bike to bike, how they read, how you lean when you check the stick, how much oil has drained down, etc - no matter how much you try to replicate the same conditions (run time, cool down time, etc) there are always discrepancies. So I add my 4 "fast-poured" quarts to the engine and then I pour the leftover old oil back into the 4, now empty, quart bottles. This makes it easy for me to deliver the oil for recycling AND it lets me know how much I drained. This way I can always make sure I'm replacing as much as I'm removing AND it lets me see if the motor is burning a little oil. After a few changes you know what to expect and if anything is off you'll recognize it. I never look at a dipstick unless the oil drained/replaced are dramatically different.

If your a strictly "by the book" kind of person and you absolutely have to check the dipstick then: Start the engine and let it idle for 3-5 minutes

Start the engine and let it idle for 3-5 minutes Stop the engine, let the bike sit for 2-3 minutes

Stop the engine, let the bike sit for 2-3 minutes Make sure the bike is on a level surface

Make sure the bike is on a level surface Remove the dipstick and wipe it clean

Remove the dipstick and wipe it clean Stand the bike upright off the sidestand

Stand the bike upright off the sidestand Insert the dipstick until it seats, but don't screw it in

Insert the dipstick until it seats, but don't screw it in Remove the dipstick and check the level

Remove the dipstick and check the level

If you decide to use the "book" method please keep in mind what I've mentioned above. I am generally ALWAYS a "by the book" kind of guy when working on these things, but this is one time when I trust my real world experience over what the book says.

Afterthoughts

This is a relatively simple process that even the most inexperienced rider can do with the right tools. It will make you feel more comfortable and knowledgable about your bike, you know it's getting serviced right, and you don't pay the highway robbery prices of the stealership for a simple oil change. As with all these DIY projects, the money you save can be spent on more accessories!

Labels: cambio de aceite